Sweeping initiatives on graphics, sustainability and other aspects have a big impact on top beverage company’s packaging.

A bubbly beverage needs a container with fizz.

That’s one of the driving principles behind the packaging for PepsiCo’s beverages. With a consumer demographic that skews heavily young, especially for its mainstay carbonated soft drinks (CSDs), Pepsi beverages need to impart a sense of “joy, excitement and fun,” in the words of Laurent Nielly, until recently vice president of innovation for Pepsi-Cola North America Beverages (he’s now with the PepsiCo International division). “You want people to smile when they use your brand,” Nielly says.

Packaging is the first chance to elicit that smile. PepsiCo has responded to that challenge, and numerous others, with initiative and ingenuity. PepsiCo products have been in the forefront of beverage packaging innovation, in terms of design, sustainability, technical aspects like hot filling, and other critical factors. That’s why PepsiCo has been chosenFood & Beverage Packaging’s 2008 Beverage Packager of the Year.

PepsiCo has been on the right track for awhile. Like many U.S. companies, its financial results for the most recent quarter weren’t so good: Volume for PepsiCo Beverages Americas (PAB), the division responsible for domestic beverages, was down 2.5% and profit unchanged over the same period last year. But that’s a blip on a long-term upward trend. PepsiCo-which includes Frito-Lay and Quaker Oats food products-has seen revenue and net income rise steadily for the last five years, increasing, respectively, 46% and 59% in 2007 since 2003. Beverages contributed a good portion of that increase: Revenue and operating profit for North American beverages rose 7% and 6%, respectively, in 2007 over 2006.

Half-liter bottles for several non-carbonated brands have been revamped

to use 20% less plastic (left), and the test-marketed gallon jug for

Lipton tea uses a snap-on polypropylene handle that's more ergonomic

and permits the use of PET for the bottle (right).

Flat CSDs get revamped

Pepsi has accomplished this growth despite stagnation in carbonated soft drinks. While CSDs represent a substantial part of PepsiCo’s total beverage sales (the company won’t provide a breakdown), its flat sales mirror the trend in the industry as a whole: CSD volume dropped 0.6% in North America from 2002 to 2007, and will drop another 8% from 2007 to 2012, according to Euromonitor International.But non-carbonated drinks are driving PepsiCo’s beverage growth, with a 5% growth in volume in 2007 over 2006 (following a 14% jump the previous year). Among non-carbonated product offerings, Lipton iced teas (in a partnership with Unilever), Aquafina plain and flavored water, SoBe water and other brands experienced double-digit growth.

But PepsiCo has not given up on CSDs-far from it. In mid-October, the company announced a major reinvestment in its CSD line, including comprehensive revamps to the logos and graphics for its Pepsi, Mountain Dew and Sierra Mist lines, which will start rolling out early next year. (Visitwww.foodandbeveragepackaging.comfor a link to view these designs online.)

“We’re quite proud of just how beautifully those new designs will show up in the marketplace and will show a very different identity for each of those brands,” says Robert Lewis, vice president of worldwide beverage packaging and equipment development.

The CSD revamp is a continuation of ongoing packaging initiatives at PepsiCo. Perhaps the widest-ranging recent one was the use of rotating backgrounds on labeling for Pepsi and other flagship brands. In a program started early last year, the backgrounds on PepsiCo cans and bottles rotate throughout the year (while the logo and other major graphic elements remain the same), resulting in 35 different looks in a year.

Other recent packaging innovations include:

• A lightweighting initiative for non-carbonated drinks that ended up reducing the amount of plastic used for bottles of products like Lipton iced tea, Tropicana juice drinks and Aquafina water by 20%.

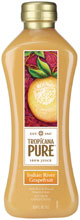

• An elegant new polyethylene terephthalate (PET) bottle for Tropicana Pure that features a tall, subtly tapered waist and a no-look label with an sophisticated, Impressionist-style illustrative panel.

• A 16-ounce reclosable aluminum bottle for Mountain Dew, from CCL Container, with full-body labels designed by young “outsider” artists. This is part of Mountain Dew’s reinvention, years ago, as a brand that appeals especially to youth.

• Ethos water, produced as part of PepsiCo’s joint venture with Starbucks, which features an extremely spare, tapered design with minimal label graphics. This approach reinforces the purity aspect of the product, in more ways than one: The label calls attention to the fact that a portion of the products’ profits will be contributed to clean-water projects in developing nations.

• A gallon jug for Lipton, currently in test market, with a snap-on handle that makes for easier handling and pouring for consumers. With this snap-on handle design, Pepsi was able to use PET for the container (a hand-through handle jug can’t be made out of one piece of PET).

Nielly explains, “We wanted to make the jug out of PET to provide better quality cues through material clarity and better package design while promoting our sustainability agenda. The constraint was how to have a hand-through handle for a PET package-the snap-on handle was the unlock.”

The entire jug is recyclable. The polypropylene handle and cap can go into the PET stream and are then separated out.

• On the international front, Pepsi Raw, a version of Pepsi distributed in the United Kingdom, that is sweetened with cane sugar and is bottled in glass. The bottle enables the product to be tunnel-pasteurized, which allows it to be formulated without preservatives.

A special promotion for Mountain Dew used aluminum bottles--the first for a carbonated beverage--and designs by trendy young artists.

Packaging fun

PepsiCo’s packaging has to achieve shelf presence within the general context of soft drinks: a fun, refreshing consumption occasion, with a disproportionately young consumer base.“With consumers requesting more specificity, more connection to the different brands and products, that in turn is going to put packaging in a real important role in that clutter,” Nielly says. “In that kind of proliferation of products, how can you use packaging as being a medium, as a vehicle to differentiate yourself and convey the right message and the right imagery to the consumer?”

The way to do that is, simply, to learn from the consumer.

“We do a fair amount of back and forth with consumers to understand and triangulate that we’re on target,” Lewis says.

Learning from consumers, however, often isn’t a simple matter of asking them questions, he says: “If you’re just asking someone what do you do, they might tell you one thing that’s totally different from what they actually do.”

That’s why some of PepsiCo’s most valuable consumer insights come from direct observation. Third-party research firms literally follow consumers around and observe how they interact with Pepsi bottles in stores, in their cars and in their homes. This kind of observational research yields the kind of small details that add up to an improved connection with consumers. Last year, PepsiCo commissioned such a study that centered on single-serve bottles.

“It’s about improving the entire consumer experience-from the moment the product is spotted on shelf, to the moment the beverage is consumed, and then making the disposal of the package as simple as possible,” Nielly says. “It doesn’t need to be a major breakthrough. This can be achieved by improving each step in the package’s lifecycle.”

Nielly says. “For instance, when they are in the store and the beverage is in the cooler, if your label is not correctly oriented, then they may not find their product. The result would be that, as we design our graphics on our packaging, we might want to find a way that we have more 360-degree branding on the packaging.”

Here’s another example of a small insight: A lot of consumers like to carry beverage bottles by the neck, indicating that an ergonomically comfortable neck is a critical element of bottle design.

“We go to consumers and we really try to understand through the experience they have with our packages, what are the opportunities so that we can drive all of those hot buttons,” Nielly says.

The Tropicana Pure bottle is tall and elegant, with a tapered waist for a better look and feel.

Sustaining savings

Consumer research, of course, yields insights on a broader scale. One of the biggest is the extent to which sustainability has entered into consumers’ priorities.This spring, PAB introduced half-liter bottles for non-carbonated beverages, including Lipton Iced Tea, Tropicana juice drinks, Aquafina FlavorSplash and Aquafina Alive brands, that use 20% less PET. PepsiCo claims that the new designs will save 20 million pounds of plastic a year.

“The challenge was to deliver significantly lighter packaging that would provide the same shelf life as a heavier bottle, withstand the manufacturing and distribution process, yet not compromise aesthetics,” Lewis says. “After a full year of hard work, we hit the trifecta.”

(Pepsi products are actually bottled and distributed by a global network of bottlers, who work closely with PepsiCo but are independent entities.)

The half-liter bottle initiative is among the first of what will be an ongoing series of efforts on sustainability, says Denise Lefebvre, director of packaging and equipment development for Pepsi-Cola North America Beverages.

“We’ve been working very aggressively on the sustainability front, because it makes great sense for our bottlers, great sense for our business and great sense for the environment,” Lefebvre says.

When lightweighting, it’s important to make sure that consumers perceive the change in a positive way, says Robert Le Bras-Brown, vice president of packaging innovation development for PepsiCo International.

“As we take weight out of the package, once the consumer receives that package and opens it, we want their experience to still be an optimal one,”

Le Bras-Brown says. “How do we work the plastic in a structural way so that we’re actually taking plastic out, but maintaining the same feel in terms of squeeze, rigidity and performance?”

That’s another area in which consumer research is helpful. The battery of tests on lightweighted bottles, both rolled out and in development, includes sensory consumer research, in terms of both the feel and the package and the perceived difference, if any, in the product’s quality and taste.

Quality design

The importance of maintaining the right feel in a lightweighted bottle ties into a larger trend: the importance of design in general. Good bottle design is inextricably tied into the consumer’s perception of quality.“We, along with a number of other companies, are leveraging design,” Lewis says. “What’s happening in the marketplace is that, by utilizing better design, consumers’ expectations are being raised. They expect surprising value, even from something that doesn’t cost all that much.”

PepsiCo effectuates that design by using third-party firms. The company has no in-house design department, depending entirely outside firms.

“We take their design expertise, couple it with our technical expertise, and we use that to translate that into a design intent that actually gets delivered in an on-shelf execution,” Lewis says. “We’re looking for firms that are creative, technically capable-we want design firms that understand the various technologies that we use in the manufacture of our products, hot-fill as an example.”

The impact of a bottle’s design can be explained in terms of “moments of truth” (a concept that originated with Procter & Gamble), Nielly says. The first moment of truth is when consumers encounter the bottle on the shelf; the second is when they complete their experience with the packaging.

“To understand that, you can’t go with a standard, one-size-fits-all statement,” Nielly says. “It forces us to go deeper and deeper into understanding the interaction of the consumer and the specific package.” F&BP

FOR MORE INFORMATION

CCL Container724-981-4420

SIDEBAR: Three divisions mean more efficiency

Last year, PepsiCo underwent a divisional reorganization that transformed its two business units (Pepsi-Cola North America and PepsiCo International) into three: PepsiCo Americas Beverages, which comprises PepsiCo Beverages North America and Pepsi’s Latin America business; PepsiCo International, which handles all foreign business outside Latin America; and PepsiCo Americas Foods, which includes Frito-Lay and Quaker.CEO Indra Nooyi described the reorganization as a way to better handle PepsiCo’s growing overall business (sales of $39 billion last year). Laurent Nielly, until recently vice president of innovation for Pepsi-Cola North America Beverages (he’s now vice president of marketing for non-carbonated beverages with PepsiCo International), says that the companywide packaging development structure was in place before the divisional reorganization, and has remained largely unchanged.

But the reorganization has made things more efficient, Nielly says: “It helped us accelerate the transfer of best practices across different business units and sectors.” For one thing, it allows PepsiCo’s beverage people to tap into a wider pool of consumer research.

“I can more easily sit down with my colleagues in Chicago who are working on Tropicana or Gatorade, and try to find out, what are their findings? What are they trying to explore with consumers?” Nielly says. “And I can build on that because, although I’m working on a different set of beverages, sometimes the opportunities and the challenges are pretty similar.”

The bottle for the Tiger Woods version of Gatorade originated in Mexico, spread overseas and then migrated to the U.S.

SIDEBAR: When in Rome (or India, China, Germany, Mexico...)

PepsiCo International, the company division that handles overseas sales outside Latin America, accounted for 26% of PepsiCo’s net revenue in 2007. (That figure includes food as well as beverages.) Catering to those markets means accounting for many local variables, including local tastes, economic conditions, regulations and climate.Polyethylene terephthalate (PET) single- and multi-serve bottles are PepsiCo’s workhorse packages across the world, says Robert Le Bras-Brown, vice president of packaging innovation development for PepsiCo International and Pepsi-Cola North America Beverages. But many differences among markets must be taken into account. One of the most important factors is economic, especially in the developing world.

“In certain emerging markets, plain out-of-pocket affordability is an issue,” Le Bras-Brown says. “In India, where a consumer might only have five rupees [10 cents] in their pocket, [the preferred package] might be a 200-milliliter glass returnable bottle that you drink at the point of purchase.” Conversely, in countries like Mexico where large families tend to be the norm, Pepsi can find itself competing against 3-liter cola bottles.

Local regulations are another consideration. In Germany and other Western European countries, strict environmental laws require returnable or recyclable packaging, leading to the use of heavyweight returnable bottles that can go through multiple cycles. Climate is another big factor, especially in regions like the Middle East and Asia-Pacific, where heat and lack of refrigeration have a profound influence on packaging protection requirements.

More generally, consumer attitudes and issues in developing versus developed nations make for basic differences in packaging structure. In countries that don’t have a good history of consumer product protection, consumers have what Le Bras-Brown calls a “trust issue.” This might require more product protection than a bottle marketed in a developed nation.

“They know when they buy a PepsiCo product, they’re getting a great product, and part of that reassurance might be, for example, an induction liner underneath a sports cap,” Le Bras-Brown says. “They know that that’s factory-fresh. You go to the European market, those concerns are not there, and that would be deemed an inconvenience. We have to adapt our understanding to the local market rationale to say, where does the consumer need reassurance versus simplicity and convenience.”

Laurent Nielly, vice president of marketing for non-carbonated beverages with PepsiCo International, says there is synergy between PepsiCo’s international and North American packaging development.

“With the packaging development organization being global by nature, I can tap into markets outside of the Americas to say, ‘Hey, what are the new things that you’ve brought to bear, what was the response from consumers, and what was the role of packaging?’ And I can then try to adapt those insights and prototypes to the U.S.”

As an example of this kind of synergy, Nielly pointed to a bottle for Gatorade Tiger, so named because it’s endorsed by golfer Tiger Woods. The 16.9-ounce PET bottle was introduced in Mexico in 2005 and rolled out in Asia and other regions since then. Its tall, thin shape and high, narrow label help distinguish it among mostly generic sports-drink bottles it competes with. It was brought over to the U.S. this year.

WEB-EXCLUSIVE SIDEBAR: 4Sight lends insight to Pepsi

Having no in-house package design department, PepsiCo depends entirely on third-party design firms for packaging innovations. One of the most significant such partnerships has been with 4Sight Inc.4Sight has done structural design innovations on PepsiCo beverages for a dozen years, across all major lines, including Pepsi, Gatorade, Aquafina and Lipton. 4Sight president Stuart Leslie estimates that his firm has designed “several hundred at least” stock-keeping units for Pepsi.

Recent 4Sight projects for Pepsi include single-serve and half-liter polyethylene terephthalate (PET) bottles for Lipton and other non-carbonated drinks, and bottles for the new 20-ounce Pepsi PET bottle with an embossed logo.

Leslie credits his firm’s success to long-standing teamwork with Pepsi. He talks with pride about the Pepsi executive who, just before they did a joint presentation at a conference, told him, “You know what’s funny is, you guys have never felt like you were a separate firm. You’ve always felt like you were just Pepsi.”

This long collaboration means PepsiCo knows what to ask for, and expect, when it deals with 4Sight.

“Usually, with Pepsi, they’ve fairly well defined a very strong need,” Leslie says. “They’ll come to us with a pretty tight brief and they’ll say, ‘Here’s what we want to communicate with this brand. We’ve got some new positioning of the brand, and we want to say something entirely different about our product now.’” 4Sight maintains contact with Pepsi personnel throughout the project-usually with the R&D team, but also with brand managers, marketing, operations personnel, molders and equipment manufacturers, depending on the individual project’s needs.

One of the biggest changes in how consumer goods companies interact with design firms is that economics now plays a bigger part.

“There was a time when design firms looked at structural packaging and said, ‘We’re going to create something that’s so cool that you’re going to sell a lot more product, therefore it’s worth spending a lot more money on,’” Leslie says. That attitude eventually began to wear thin: “The challenge now is, how do we develop something that the consumer is really excited about but uses less plastic or runs more efficiently, and allows the company to run more profitably.”

FOR MORE INFORMATION

4Sight Inc.

212-253-0525