Much of the groundwork has already been laid. We just need to continue building improvements in from there.

The cutting-edge packaging line of the future will be affected by many forces. Some will be internal. Packagers will always be looking to cut costs and packaging material, labor and efficiency is always a possibility. Market forces will drive progress as customers demand more innovative packaging and competitors supply it. A third force is societal. Packaging, mostly wrongly, has a reputation of being wasteful of resources, as well as taking excessive space in landfills. Packagers will need to make packaging greener.

So here is one prediction of what the packaging line of the future will look like:

First and foremost, the packaging line of the future will be flexible. The age of mass customization is truly upon us with consumers demanding what they want, how, when and where they want it. Marketing channels, each with different requirements, are proliferating. Traditional outlets must compete with hypermarkets, convenience stores, club stores, dollar stores and boutique food marts, as well as specialty stores and other outlets. A product like Coca-Cola-which was available in a single flavor/size/style as recently as the mid-’60s-is now produced in more than 150 combinations This does not include the many non-Coca-Cola variations such as Sprite and other flavors. The line that seldom if ever needed to introduce a new product may now need to introduce one every month. Flexibility in the line design is required to allow it to accommodate these unknown future products in a timely and cost-effective manner.

This explosion of products has meant the death of the dedicated line. Most packaging lines must be changed over several times a week. In some cases, several times a day. Eight- to 12-hour changeovers are no longer acceptable. Changeovers within 10 minutes will become the goal. Changeover will need to be, as Paul Zepf of Zarpac says: “No time, no tools, no talent, no tinkering.” It must be easily performed in a minimal amount of time by semi-skilled operators with the line running at full efficiency immediately at restart. The line of the future will be designed with this concept in mind. Machine builders will finally realize this and design their machines for flexibility.

Technology will advance flexibility. In recent years individual servo motors have been replacing the traditional main motor using cams, chains and linkages to drive machine functions. Servos eliminate much mechanism and simplify machine construction and maintenance while improving reliability. They also allow functionality not possible before.

For example, before servos, it was impossible to measure individual cap torque. As servos replace mechanical clutches and drives, they allow the on-torque of every cap to be measured and recorded. More importantly, they allow the torque to be set and controlled via software. This eliminates the need for a mechanic with wrenches, as well as the downtime and inaccuracies inherent in mechanical adjustment. Setting is done by the operator selecting the product name from the control panel.

Servo motors are also being used on cartoner flap tuckers, thermoformer platens, flowrapper metering conveyors and other functions. As they will continue to decrease in price and increase in functionality, by 2019 they will supply all power on packaging machines. As this happens, daily changeover will become fully automatic. New product introductions will be hastened and simplified as modifications will be made by programming rather than replacing parts.

Communications will be standardized. Presently it can be difficult for different machines to communicate with each other as required for smooth line operation. The Organization for Machine Automation and Control (OMAC) is working to establish standards that all machine builders will adhere to. This uniform set of standards will ease maintenance, as technicians will only have to learn a single set of operational protocols. This will result in smoother operation and less downtime.

Changes in machine construction will result in changes to the plant workforce. No longer will there be large numbers of operators and technicians. Machines will become more autonomous, reducing or eliminating the need for semi-skilled operators. Components and product will feed to the line directly from storage with no handling. Finished product will be palletized and placed on an Automatically Guided Vehicle (AGV). The AGV will transport the product to the warehouse or a waiting truck, never being touched by humans.

The line will be autonomous not only in operation but in diagnostics and repair as well. Sophisticated computer control systems will monitor every aspect of operation. Sensors will detect impending problems and either repair them via software commands where possible or alert the technician before line operation can be affected. Most current alarm systems are hopelessly dumb. The line of the future will send a message to the technician’s smart phone at the first hint of malfunction. That message will not only announce the problem, it will prioritize it, give details on its nature and advise the materials and tools required to resolve it. When the technician arrives at the line they will not only know exactly what they need to do, they will have everything necessary, eliminating the need to chase back to the tool room.

This puts an almost scary burden on the technician. Although the machine will tell them what to do, they will require a high level of skill to do it. High levels of training will become a necessity. Packagers will demand and machine builders will provide programs to develop these skills. The traditional manual will still be available but supplemented by audio visual versions at the machine controller as well as on pocket-size wireless devices. These will allow every technician to have every scrap of information available about the machine including diagrams, parts lists and more in their pocket, wherever they may be.

Or else:

By 2019 quantum physics, nanotechnology and high-level electronics will have intersected to eliminate packaging altogether. Everyone will have their own personal transmogrifier. This will allow the consumer to simply imagine the product that they want and the transmogrifier will produce it out of thin air.

Check back in 10 years to see which vision is more accurate.

Product Name: Gulp Pulp

Description: A delicious, nutritious puree of vegetables, proteins and fruit for use as a sauce, topping or refreshing ready-to-consume snack

Flavors: Strawberry Sublime, Blueberry Bliss and Kiwi Kismet

Sizes: 12, 16, 24 and 32 fluid ounces

Refrigerate after opening.

Description: A delicious, nutritious puree of vegetables, proteins and fruit for use as a sauce, topping or refreshing ready-to-consume snack

Flavors: Strawberry Sublime, Blueberry Bliss and Kiwi Kismet

Sizes: 12, 16, 24 and 32 fluid ounces

Refrigerate after opening.

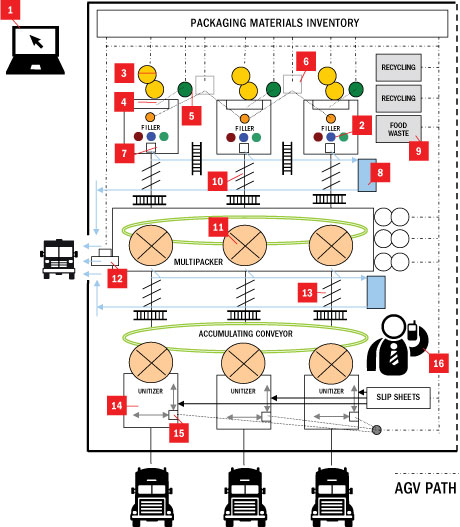

PACKAGING LINE OF 2019

1. Order is automatically generated from retail store or consumer website and directed to closest regional manufacturing center for direct-store-delivery or direct-consumer-delivery. Enterprise Resource Planning (ERP) software interfaces with line controls throughout the process.2. Product is formulated from pre-cooked ingredients and pumped to packaging lines on-demand. Red pipe conveys Strawberry Sublime; blue, Blueberry Bliss; green, Kiwi Kismet.

3. Semi-rigid, mono-material rollstock-preprinted with generic brand graphics-is brought to the aseptic filling machines by next-generation vision-controlled, robotic, automated guided vehicles (AGVs). Each filler accommodates two rolls and splicing is done automatically for continuous operation.

5. Ink for ink jet printers is automatically replenished through overhead pipes.

6. AGVs also automatically refill hoppers with easy-open and reclosable metering dispensing closures, which are fed to each filler, sterilized and sealed onto rollstock prior to forming, filling and final sealing.

7. X-ray unit inspects each pack as it exits filler in single file. Damaged, underweight or otherwise imperfect packages are rejected and sent to holding bin for manual visual inspection.

8. Underweight packages are accumulated, manually packed into cases and donated to charity.

9. Unsalables are automatically emptied. Product is bulk-packed and sold for use as soil nutrients to local farmers. Packages and dispensers are automatically separated and crated for recycling or in-plant waste-to-energy incineration.

10. If needed, first-in/first-out accumulating conveyor holds up to six minutes of packages.

11. Packs enter multipacking station and are collated/organized by pick-and-place robots into same-flavor or mixed-flavor 3x3 cubes, which are then wrapped with a clear film that’s specially treated to prevent any horizontal movement when multipacks are vertically stacked.

12. Consumer orders exit left, and a mailing label is immediately printed and applied. Packs are shipped via commercial carrier. Multiple stations can be set up as needed when direct-to-consumer deliveries increase.

13. If needed, first-in/first-out accumulating conveyor holds up to six minutes of multipacks.

14. Robotic unitizers hold hundreds of patterns. Each robot automatically reads electronic product codes and picks appropriate multipacks from the looped conveyor for the specific order. Each unitized load is delivered directly to the store on-demand, so standard slip sheets now measure 20 x 24 inches. Unitized loads are double-stacked prior to being automatically loaded into waiting trucks.

15. Traversing printer (in three dimensions) codes customer-specific order data on unitized-load label (human- and machine-readable), and applicator wraps labels around opposite corners so all sides are tagged. Ink is piped to printers from stored bulk supply, and labels are automatically replenished by AGVs. Individual package graphics create high-impact billboards for end-aisle or club-store displays.

16. The 24/7 lights-out facility requires just one employee to monitor the lines. Section lighting turns on when it senses the person’s photo ID is within a 10-yard area. Any alerts are automatically sent to the operator’s wireless device with Bluetooth headset (wireless service is on a secured network) with specific problem and solution(s) identified. Otherwise, the worker is free to listen to audio of his/her choice.