Allpax Products (www.allpax.com), powered by Pro Mach (www.promachinc.com), is now offering a waste-steam recovery system for retorts that is designed to lower energy costs, reduce consumption of water, and improve the overall sustainability of the facility. This new system is suitable for both new installations and as a retrofit solution.

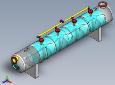

In every retort operation the FDA requires retorts to be purged of residual atmosphere before the shelf-stable process begins. In the “come-up vent-open” process, steam is flushed through the retort and vented out of the facility for a specified period of time. The Allpax waste-heat recovery system captures the “come-up vent-open” waste steam in a vented tank where the steam condensates into hot water of about 200˚ F.

This hot water can be used to supplement hot water in lavatories and cleaning stations or it can be run through heat exchangers for heating food or other processes at the plant. One of the first companies to use the new system utilizes the steam for use with a heat exchanger. Heat exchanged water is returned to the Allpax collection tank in a closed loop heat recovery system.

The vented collection tank is pressure neutral in terms of “come-up vent-open” guidelines. In other words, the Allpax tank is engineered to have virtually the same pressure characteristics as an open vent pipe. The heat recovery system is PLC controlled and equipped with pressure sensors, ensuring that operations personnel will be alerted should deviations in specified pressure occur. Tanks are sized to the needs of the operation. The system is easily turned on or off, depending on production schedules. Return on investment should average three years for a mid-sized retort room. As energy prices rise, return on investment speeds up.