|

| All-in-one systems feature automated technologies and standardized operating procedures that allow operators to control all parts of the entities the same way. |

In this three-column series, Bosch Packaging Technology shares its wealth of information to help manufacturers optimize their horizontal packaging lines.

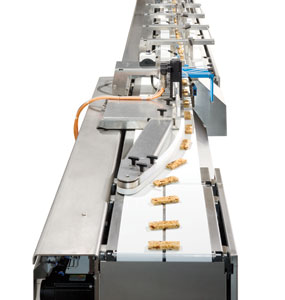

When Aristotle said the ‘whole is greater than the sum of its parts,’ he’d never have guessed this would apply to sophisticated packaging lines for bars. Bar packaging comprises one of the fastest and most efficient processes in the packaging world, with equipment transporting products in all shapes and sizes at dizzying speeds. However, this process can be even further expedited by incorporating a single design philosophy across the line as opposed to using a line composed of individual components that are not properly or adequately integrated. This seamless approach makes operation as simple as possible for the operator.

Machinery running on different operating systems and from different suppliers may well result in production lines with ten or more different control panels. This can completely overwhelm operators struggling to meet high productivity and efficiency standards and easily lead to errors due to incorrect operation, handling and response. The result is lengthy breaks in production.

To drastically reduce the potential for error on bar packaging lines, operators need systems they can understand and easily handle. A single design philosophy provides one look, one feel so that the entire line can be operated as one. All-in-one systems feature automated technologies and standardized operating procedures that allow operators to control all parts of the entities the same way. For example, the Bosch bar packaging line features only one operating panel philosophy.

In addition, easier and quicker operation and a higher degree of automation allow staff more time to attend to other tasks to increase uptime. It also enables staff to take on more responsibility and reduces the need for extensive training, making the overall flow of production more reliable and easier to control.

As the keepers of maintenance, cleaning and error response, the operator has a huge impact on overall equipment effectiveness (OEE). As a result, it is crucial to integrate a bar packaging system that is very quick and easy to clean and to maintain, with easily accessible parts.

Changeover can also be a bottleneck on bar packaging lines. Traditionally, format changes would stop production across the entire bar line for extended periods of time. Opting for a bar packaging line that offers standardized tools, easy operating technology and accessibility enables operators to complete format changes quickly and with minimal interference in the production process.

As a supplier of a seamless packaging system, Bosch encourages manufacturers to make use of a new generation of lines to boost productivity and therefore, profits.

Bosch featured its bar packaging system at the recent Pack Expo Las Vegas, highlighting new wrapping speeds of up to 1,500 bars per minute.

About Bosch Packaging Technology

Based in Waiblingen near Stuttgart, Germany, the Bosch Packaging Technology division is one of the leading suppliers of process and packaging technology. About 4,700 associates at over 40 locations in over 15 countries worldwide develop and produce complete solutions for the pharmaceuticals, foods, and confectionery industries. These are complemented by a comprehensive after-sales service portfolio. The global service and sales network provides customers with local contacts. Additional information is available online at www.boschpackaging.com.