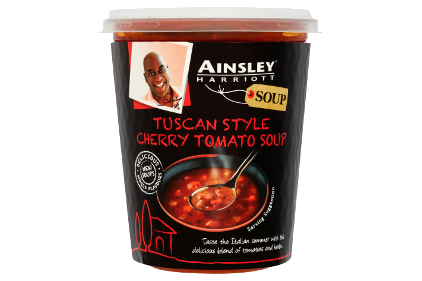

The Ainsley Harriott brand is to expand its current range of products with the market's first-ever soup product to be stored at ambient temperature and packaged in a tub design.

A unique packaging solution from Clondalkin Group (clondalkingroup.com) company Chadwicks (chadwicks-lids.com / chadwicks-sleeves.com) means this brand first from Symington's will have the premium look and feel of fresh soup with a shelf life of up to 12 months.

Chadwicks' technical team created a UV flexo foil recessed lid which enables the soup pots to be filled at very high temperatures. The double recessed lid allows for contraction during the cooling process.

Craig Roach, head of Bought in Goods at Symington's explained: "During the development phase panelling on the pots was a key challenge. We have to fill at extremely high temperatures and as the product cooled and contracted it created a vacuum and caused the pots to distort.

"Chadwicks are valued in the industry for their customer service and technical expertise and so we turned to them to leverage their knowledge of this pack format. They immediately identified the issue and were able to provide a solution in a very short time frame.Chadwicks' 'Top Hat' lid creates an air space allowing for 'pull down' during the cooling process so it's the lid that contracts and not the container.

"The new range will see the brand enter the ambient aisle with a format that takes its packaging cues from the fresh aisle."

Martin Hardman, sales and marketing director at Chadwicks added: "We have years of experience of providing lidding solutions for both hot and cold fillings and we're delighted that our hot fill lid solution has proved such a success for this exciting new product range. We have a highly skilled technical team at Chadwicks and pride ourselves on our ability to innovate and deliver creative and functional packaging solutions for clients."

Clondalkin Group company Chadwicks is a key supplier of flexible packaging solutions in the food, dairy, beverage and pharmaceutical sectors. The company is a pioneer and continues to innovate, leading competitors in the production of lids and shrink sleeve packaging solutions. The company is one of 20 production facilities operating throughout Europe and North America under Clondalkin Group’s Flexible Packaging Division.